Description

The manual continuous batch washer Aquabox 500 lava efficiently the various models of boxes used in central processing of fruits and vegetables, refrigerators, dairy, among other segments using plastic boxes on your plants.

Developed to meet plants with low daily turnover boxes.

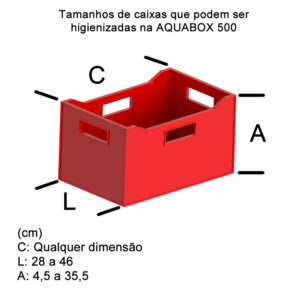

The drive system is manual boxes, that is, without belt, The operator pushes a box behind the outra.Possui a top and two side guide for adjustment according to the size of the box.

Na AQUABOX 500, the boxes are cleaned in two stages :

- INTERNSHIP 1:Removal of the heaviest dirt with high impact jets;

At this stage the boxes receive high impact jets with hot or cold water(optional) and detergent(if chosen its use). It is recommended the use of hot water at this stage to improve the cleaning performance.

- INTERNSHIP 2: Rinse with clean water network + sanetizante(peracetic acid- optional );

At this stage the boxes are rinsed with clean water network + sanetizante(optional). This water moves to the stage 1 which is reused for washing.

Importantly, the ability sanitized boxes per hour and time required for all the boxes back to original form( clean), It will depend on the degree of impregnation thereof. That is, the higher the degree of impregnation of a box or elapsed time without cleans it, the greater the number of cycles needed to bring it to its original state.

Benefits:

- High productivity;

- More savings of water and detergent;

- Convenience and simplicity in its operation;

- Robust and low maintenance;

- Within the safety standards;

- High cleaning efficiency;

|

Technical data |

|

| Designation | manual continuous batch washer Aquabox 500 |

| Water consumption(m³/h) | 0,6m³/h ( maximum-pressure consumption of the network 2 bar) Obs: the flow rate can be adjusted |

| maximum working temperature(ºC) | 70 |

| Number of people to operate the machine | 1 at 2 people |

| Meets the standards | NR-10; NR-12; NR-17 |

| System moving boxes | Manual( without conveyor for moving boxes) |

| Minimum space for the placement machine(m) | 5,7X3,07(17,49m²) |

| Tension(v) | 220 or 380 three-phase |

| Capacity | 500 a 800 (depending on the degree of the impregnation box) |

| Water Heating | Electrical or steam(optional) |

|

optional |

|

| Reference | description |

| – | outfeed conveyor in curve |

| – | straight track roller |

| SAS-20 | System application sanetizante |

| SAD-20 | Detergent application system |

| – | Steam heating system |